Category

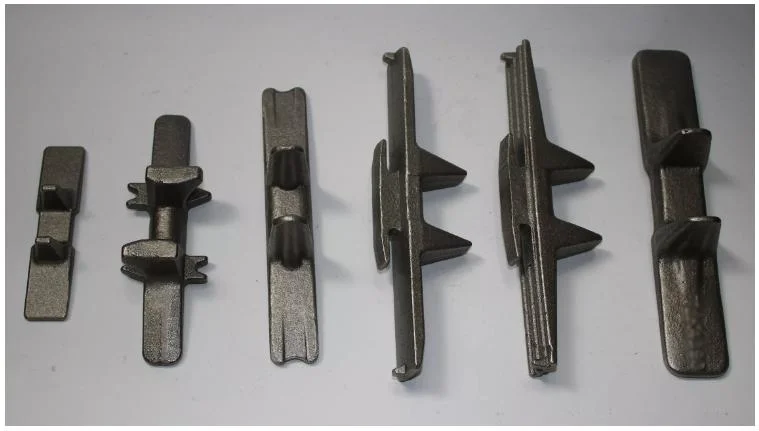

Syi OEM Undercarriage Rubber Belt Track Cast Iron Metal Adi Casting Core

SYI Austempered Ductile Iron ADI Castings Iron Teeth For Rubber Track Description Austempered Ductile Iron (ADI) Casting

Basic Info

| Model NO. | Rubber Track Iron Core |

| Production Capacity | 10000 Kilogram/Kilograms Per Month |

Product Description

SYI Austempered Ductile Iron ADI Castings Iron Teeth For Rubber Track

DescriptionAustempered Ductile Iron (ADI) Castings, It's a process that make cast iron parts by isothermal quenching heat treatment, To make the ductile iron parts obtain Austenitic matrix which formed by acicular ferrite and Carbon-rich austenite. Reference standard:GB/T 24733--2009ISO 17804:2005ASTM A897--2006ADI has high strength, high toughness and high hardness, good vibration absorption and good manufacturing process.Meanwhile, it has the characteristics of good wear resistance, high bending fatigue, contact fatigue strength, it also can reduce the weight of the product under the same strength condition.Performance:| Grade of DCI | Tensile strength (MPa) | Yield strength(MPa) | Elongation (%) | Brinell hardness (HB) |

| QTD800--10 | 800 | 500 | 10 | 250--310 |

| QTD900--8 | 900 | 600 | 8 | 270--340 |

| QTD1050--6 | 1050 | 700 | 6 | 310--380 |

| QTD1200--3 | 1200 | 850 | 3 | 340--420 |

| QTD1400--1 | 1400 | 1100 | 1 | 380--480 |